Project Gallery

Below are 3 pictorial examples of projects.

The first is a One-off Project, the second a Limited Production Project and the third a Production Project, utilizing BCT's computer controlled, heated mold technology.

The slide shows are not set to auto-start, so use the start buttom below the image to start.

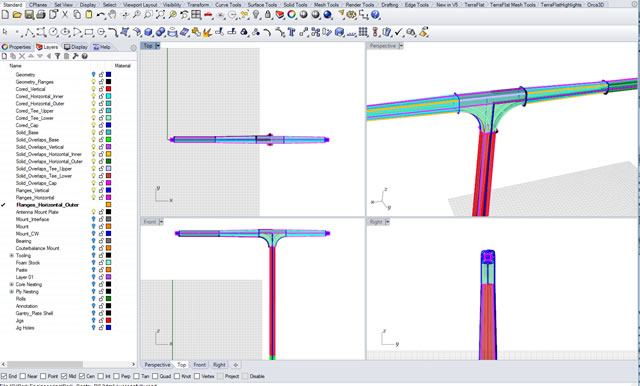

Very Large Spherical Nearfield Gantry - One-off

The customer provided BCT with vertical height (50 feet), horizontal extension (36 feet) and payload (antenna and its positioner - 150 lbs.) requirements. BCT then designed, analyzed, tooled and maufactured the gantry

Because of the length of the cantilever and the payload mass, BCT created a counter balanced Tee-shape gantry. This way the deflection through its rotation is kept planar and can be corrected by a single lookup table when positioning.

Click on the button to the right, if you have Google Earth installed on your computer. Google Earth of Gantry

- Gantry_CAD1.jpg

Gantry CAD

- Gantry_FEA1.jpg

FEA Results

- Gatry_lam.jpg

One of the Laminate Schedules

- Gantry_mold_surfaces.jpg

Mold Surfaces

- Gantry_CAM.jpg

CAM for Tooling

- DSC00278.jpg

Bonding of Foam

- DSC00388.JPG

Machining of PU Foam for One-off Mold

- DSC00387.JPG

Foam Ready to have Paste Applied

- DSC00287.JPG

Pasted Foam being Post-Cured

- DSC00293.JPG

Machining of Paste

- DSC00443.JPG

Mold Sections Bonded together, Wet Sanded and Released

- DSC00472.JPG

Lamination of Half of a Vertical Section

- DSC00501.JPG

Molded Parts for Gantry

- DSC00513.JPG

Parts in Paint Booth

- DSC00520.JPG

Bonding and Bolting of Components

- DSC00651.JPG

Assembly Fixture for Mount Interface Plates

- DSC00666.JPG

Plates Bolted and Bonded

- DSC00774.JPG

Pre-assembled Major Components Loaded in Truck

- DSC_0012.JPG

Major Conmponents Assembled on Site

- IMG_6285.JPG

Dedication Ceremony of Sperical Nearfield Scanner

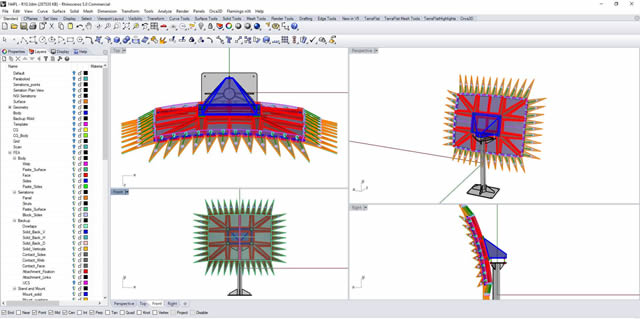

Compact Range Reflector - Limited Production

The customer provided the required focal length, quiet zone diameter and the plan view of the serration profiles. BCT designed the reflector, developed the laminates in the structure, performed FEA analysis, machined and manufactured the required limited production tooling and manufactured the reflector.

Additionally, BCT designed a unique transport/shipping dolly that converts itself into a lifting fixture for the reflector installation.

The finished reflector body's surface had a RMS of .0005"

- 1-CAD.jpg

CAD Modeling of Compact Range Reflector

- FEA_lam_areas.jpg

FEA Mesh and Laminate Areas

- 2_FEA.jpg

FEA Results

- Backup_master_surface.jpg

Backup Master Surface

- 3_CAM.jpg

CAM Simulation

- IMG_0389.jpg

Bonded Body Foam on Mill for Machining

- 4-Backup Foam.jpg

Backup Structure Master Foam Machined

- 5_Backup Paste.jpg

Backup Structure and Body Masters Pasted

- DSC01290.jpg

Body Master being Rough Machined

- DSC01305.jpg

Backup Master Machined and Duratec Applied

- DSC01317.jpg

Body Master being Buffed

- DSC01340.jpg

Backup Mold on Dolly

- DSC01341.jpg

Body Mold On Dolly

- DSC01460.jpg

Molded Components being Fit

- DSC01463.jpg

Backup Structure being Bonded in Body Half

- DSC01465.jpg

Body Halves with their Backups Bonded Together

- DSC01470.jpg

Body being Prepared for Surface Pasting

- DSC01471.jpg

Body Pasted

- IMG_0438.jpg

Reflector Surface Roughing

- DSC01488.jpg

Reflector Surface Finish Passes

- DSC01343.jpg

Tooling Board being Bonded to Pre-pressed Panel for Serrations

- DSC01451.jpg

Serrations being Machined to their Unique Area of the Paraboloid

- Serration Scan.jpg

Serration Scan - RMS = 0.0015"

- IMG_0439.jpg

Machined Reflector with Molded Transition Mount attached on Work Stand

- DSC01491.jpg

Initial Wet Sanding of Primed Surface

- IMG_0444.jpg

Finish Wet Sanding against Tracking Laser Data

- Body_scan.jpg

Finished Body Scan - RMS = 0.0005"

- IMG_0448.jpg

Surface with Silver Applied

- DSC01509.jpg

Reflector Body on Shipping Dolly with Serration Hardware Attached

- DSC01529.jpg

Reflector Body loaded on Truck

- Body1.jpg

Reflector on Site and Dolly Converted to Lift Stand

- Body_lift.jpg

Reflector being Lifted on to Pedestal with Fork Truck

- IMG_0459.jpg

Serrations Installed and being Alligned

- IMG_2259.jpg

Reflector installed in Anechoic Chamber

.75M 3-Piece Fly-away Reflector - Production

The customer provided BCT with the required parameters of the parabolic shape, the basic main body width, hardware interfaces and the operating parameters that the finished reflectors had to meet. Using these provided parameters, BCT designed the reflector, its laminate structure, tooling and fixturing and then manufactured the reflectors. This project is a production example and utilizes BCT's computer controlled, heated mold technology.

BCT has produced around 400 of these reflectors.

For a run of 100 reflectors:

- The average RMS was .00253”

- The standard deviation was .00026”

- The max RMS was .0034”

- The min RMS was .0020”

- Only 4 were at or above .0030”

- 01_Cad.jpg

Reflector Solid Model

- 02_Cad.jpg

Mold Assembly Rendering

- 03_FEA.jpg

Reflector FEA Model

- 04_FEA.jpg

FEA Results

- 06_CAM.jpg

Body Master CAM

- 07_code.jpg

Wing Master NC Code

- 08_master.jpg

Body Master being Machined

- 09_fixture_block.jpg

Assembly Vacuum Fixture Block being Prepared

- 10_wing_master.jpg

Finished Wing Master

- 05_master-scan.jpg

Scan of Body Master prior to Mold Start (RMS 0.0007")

- 11_body_mold_wired.jpg

Body Mold being Wired

- 12_body_wired.jpg

Wing Mold being Wired

- 13B_controll.jpg

Process Control GUI

- 13_assembled.jpg

Mold Assembly Completed

- 05_mold scan.jpg

Finished Mold Scan (RMS 0.0007")

- 13C_3K_nesting.jpg

3K Nested for Gerber Cutting

- 14_untrimmed.jpg

Untrimmed Parts

- 15_trimmed.jpg

Trimmed Parts

- 16_fixture.jpg

Hardware being fit in Vacuum Assembly Fixture

- 17_scan.jpg

Reflector being Scanned

- 17B_scan.jpg

Assembled Reflector Scan (RMS 0.0020")

- 18_backs.jpg

Finished Reflectors

- 19_fronts.jpg

Finshed Reflectors

- truck.jpg

Reflector Operational