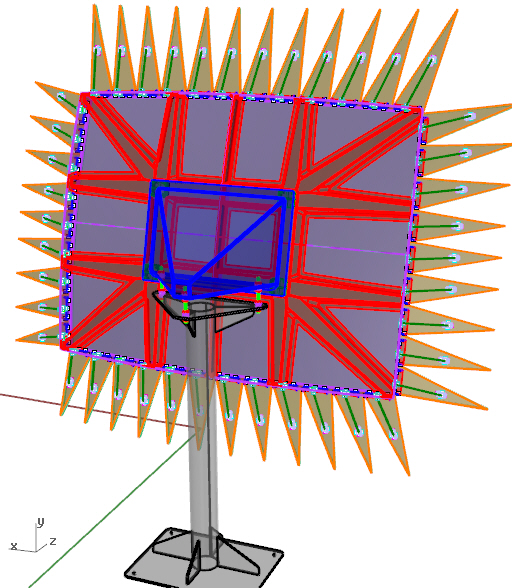

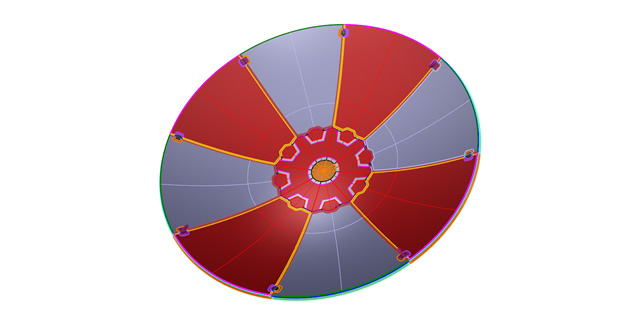

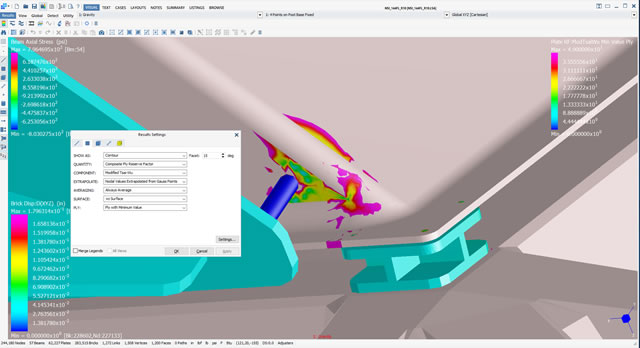

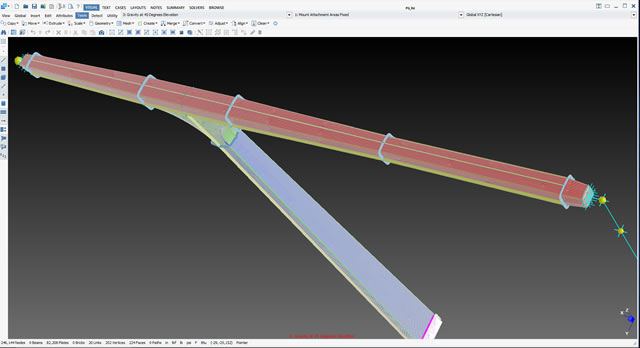

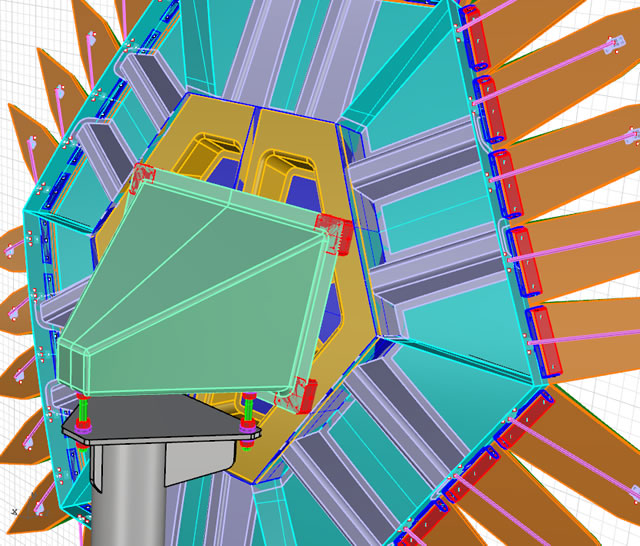

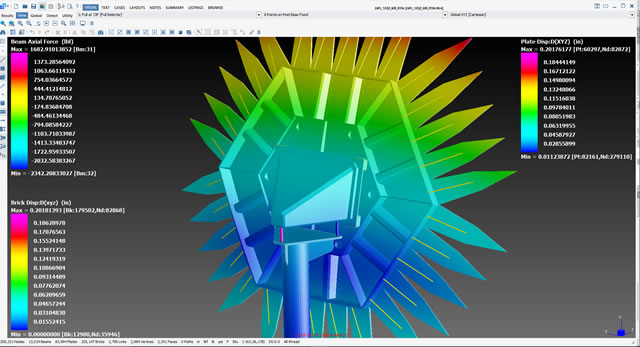

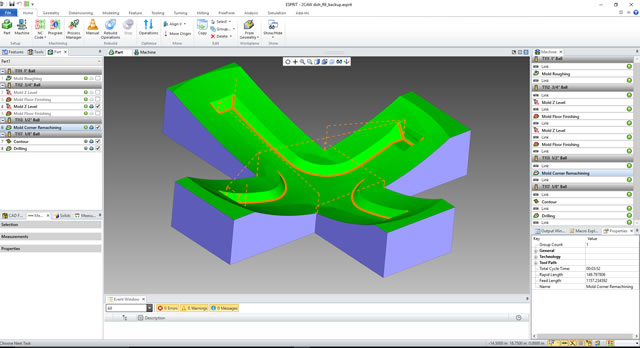

Design and Engineering

Beaufort Composite Technologies has considerable experience in the design, analysis and engineering of composite structures and their required tooling.

In today's world, the assets required for these capabilities are all computer based and BCT is fully equipped with the optimal computer program for a particular field and the skill to use them.

Composite Materials

BCT focuses on the processing of epoxy prepreg laminations.

Standard Materials used by BCT:

- Various prepreg epoxy resin systems

- Carbon fiber weaves and uni tapes

- E-Glass weaves and uni tapes

- S-Glass weaves and uni tapes

- Kevlar weaves and uni tapes

- Specialty hybrid weaves

- Film adhesives

- Honeycomb cores (Aluminum, Aramid and Polypropylene)

- Various foam cores

Molded parts have their machine cut plys kitted and then are hand laminated in the mold.

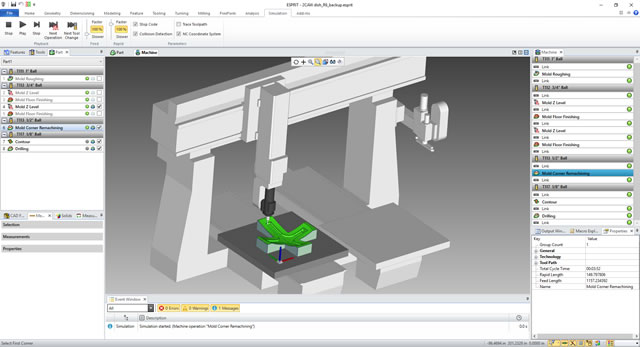

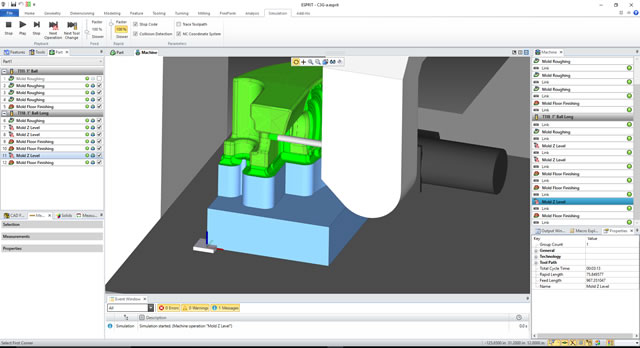

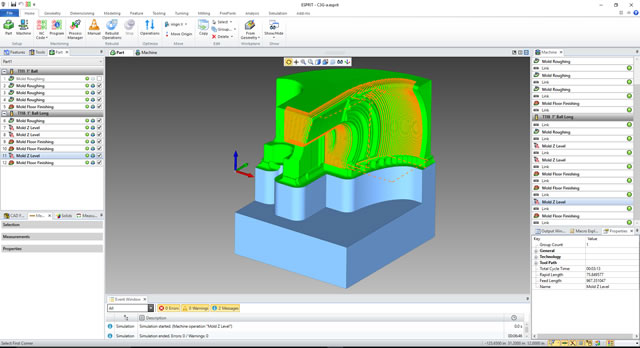

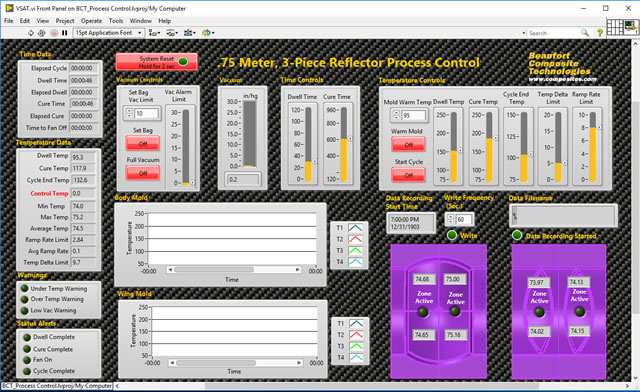

Tooling and Heated Molds

To make a composite prepreg part requires a mold and there are three basic types of molds that BCT produces.

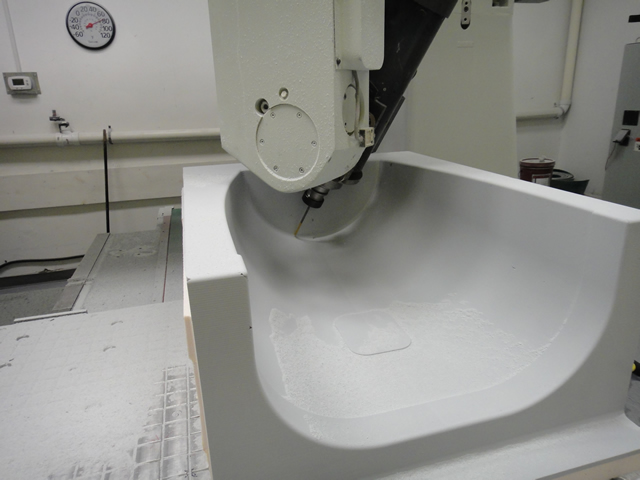

- A one-off mold from which one or two parts are to be made and generally machined as a female

- A production mold which is used in an oven to produce parts and made off of a machined master

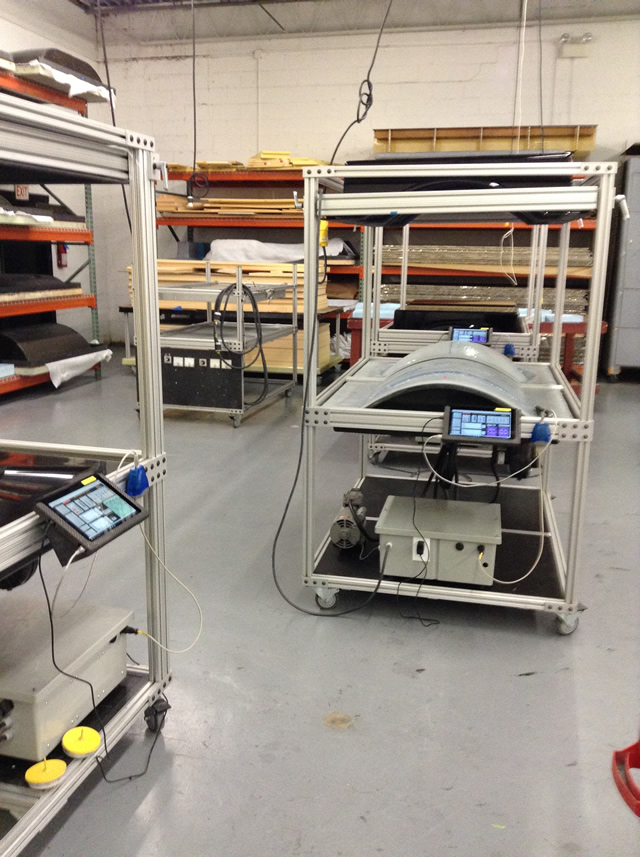

- BCT's computer controlled, heated mold that requires no oven or autoclave to produce very high quality parts

Molded Parts

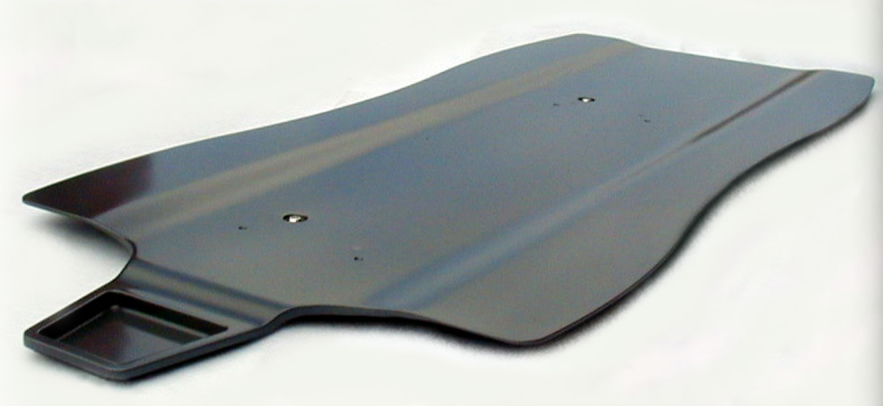

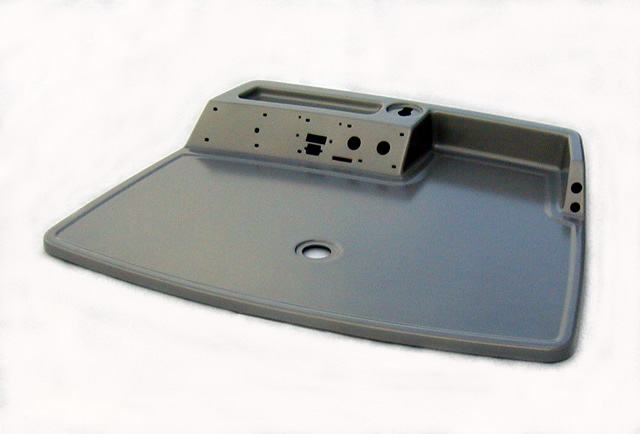

BCT produces epoxy prepreg, complex shaped, molded parts manufactured from dedicated tooling, whether be it one-off or production.

All plys are Gerber cut and numbered, assuring precise overlaps and fiber orientation and then kitted

Layers or plys are hand laminated against the mold and are then cured under vacuum in BCT's oven or in a BCT heated mold.

Molded parts generally incur some post operations in terms of trimming and drilling of holes, assembly, surface finishing and painting.

Panels and Sheets

- Custom laminate schedules according to customer specified requirements. The customer specifies ply materials and fiber orientation (0, 90, +45, -45, etc.) providing almost infinite permutations.

- Panels are laminated to yield 4 feet by 32 feet, from which the customer specifies its cutting.

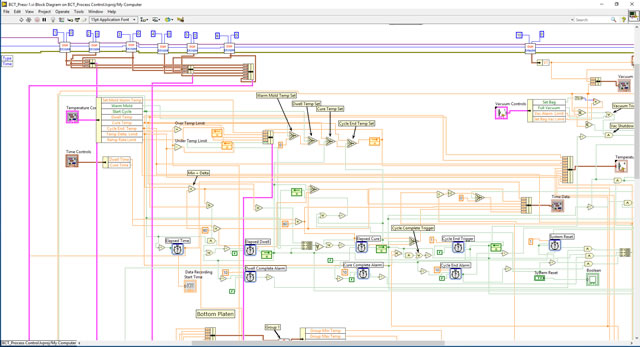

- Panels are cured under 28 inches hg and at 250F using BCT's proprietary computer controlled heated vacuum press.

Features

- Standard panels have a tg of 250F.

- Customer created laminate schedule including fiber orientation

- Customer specified cutting of panel to optimum required sizes, so as to minimize waste

- Large size availability (up to 32' long)

Options

- Peel ply finish for secondary bonding.

- Complex CNC cutting and milling of panel when CAD files are provided by the customer.