Facility

BCT's manufacturing facility is located on 5 acres in Beaufort, NC and has been at this location for the past 20 years. The plant's elevation is 12 ft. above sea level, providing the ability to achieve maximum vacuum pressure when processing prepreg laminations.

The plant is climate controlled on the material prep and lamination side, as well as the machining and painting areas. The 5-axis machining room is kept +/- 2 degrees F, when machining reflector surfaces or precision tooling.

Though not a large plant (12,000 sqft), it is extremely well equipped for its size.

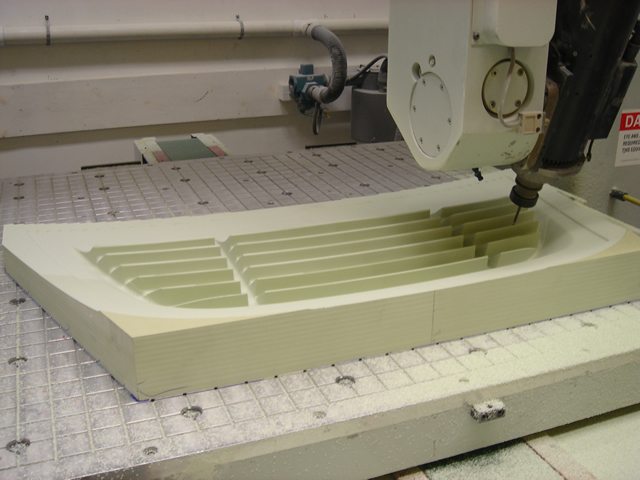

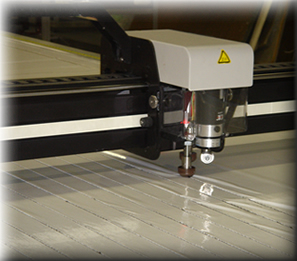

Machining Equipment

CNC machining is an intragral part of BCT's capability.

BCT has both a very long 3-axis router and a heavy duty 5-axis router. It also is equipped with all large and small power tools, as well as air tools.

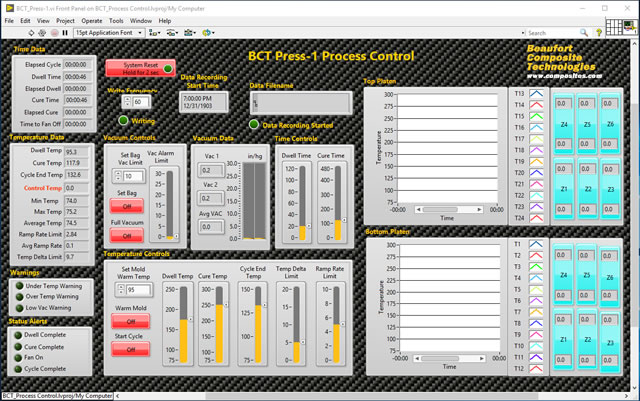

Process Equipment

BCT is extremely well equipped with equipment not often found in shops of its size.

In fact, some of BCT's equipment is unique because it was designed and constructed in-house.

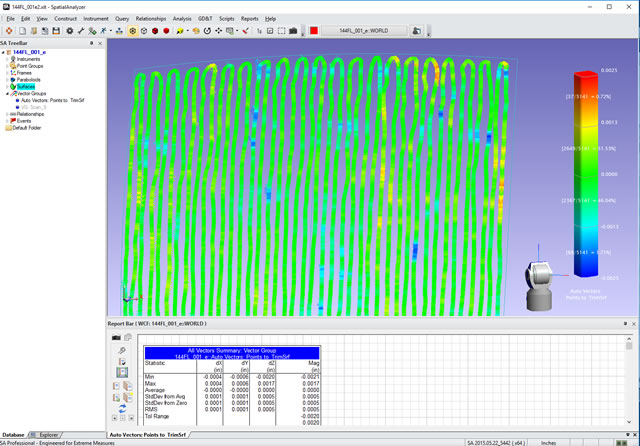

Metrology and QC Equipment

Having the ability to precisely measure surfaces is an essential part of BCT's equipment inventory.

BCT has both a tracking laser with accessories and a scanning arm, as well as other testing and measuring equipment.